In 2009, I had my furnace replaced with a new high efficiency furnace with air conditioning by a local HVAC contractor.

In 2011, I noticed the smell of smoke through the registers. Shortly after that, I noticed the compressor was still running while there was no air coming out of the registers!

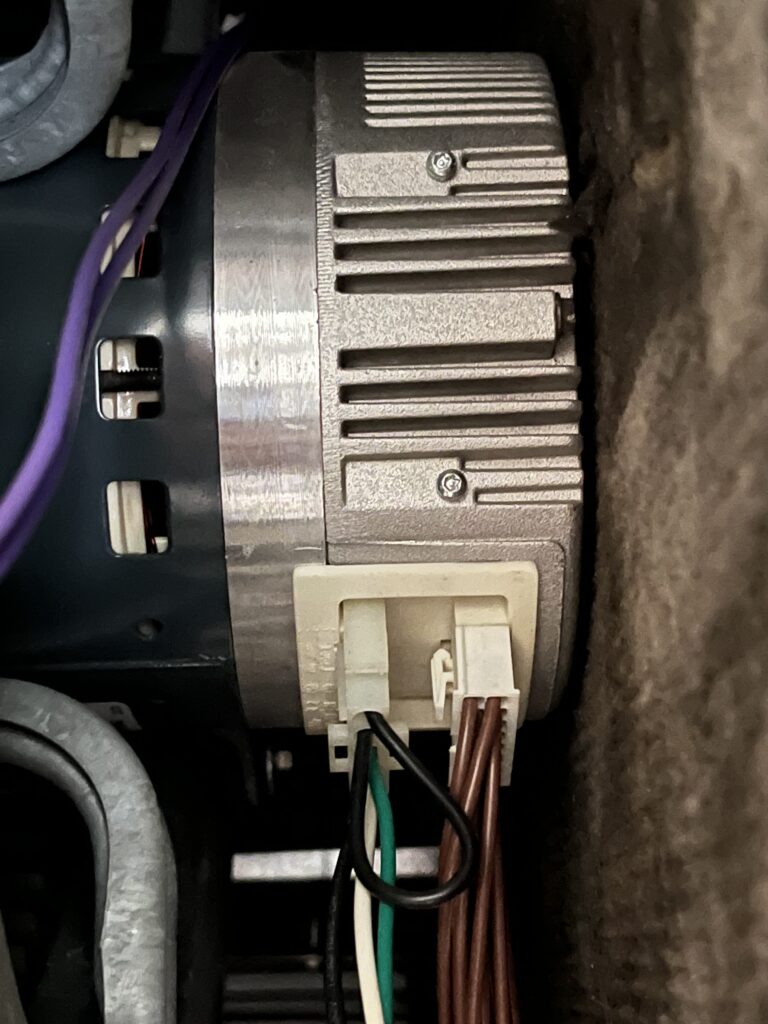

I called the company that had installed the system a few years earlier and a few days later they were able to replace the ECM motor control unit that’s attached to back of the blower motor instead of replacing the entire motor.

In 2014, the ECM motor failed again! It had the same symptoms; smoke smell, then catastrophic failure of the blower motor. After some back and forth, the HVAC company was able to get the manufacturer to replace the motor controller again under warranty. This time it took 3 weeks to get the part and install it. The new ECM motor controller had a large heat sink installed on the back of it where the original one had a simple metal casing.

Eight more years went by until the next failure. This time the smoke smell was different but the problem was exactly the same. I contacted my HVAC vendor and they came out a few days later and agreed with me that the blower motor had failed. Since I had three previous failures, they proposed replacing the entire motor for a mere $1500! It sounded reasonable to them, but not to me! I paid their $95 diagnostic fee for agreeing with my diagnoses.

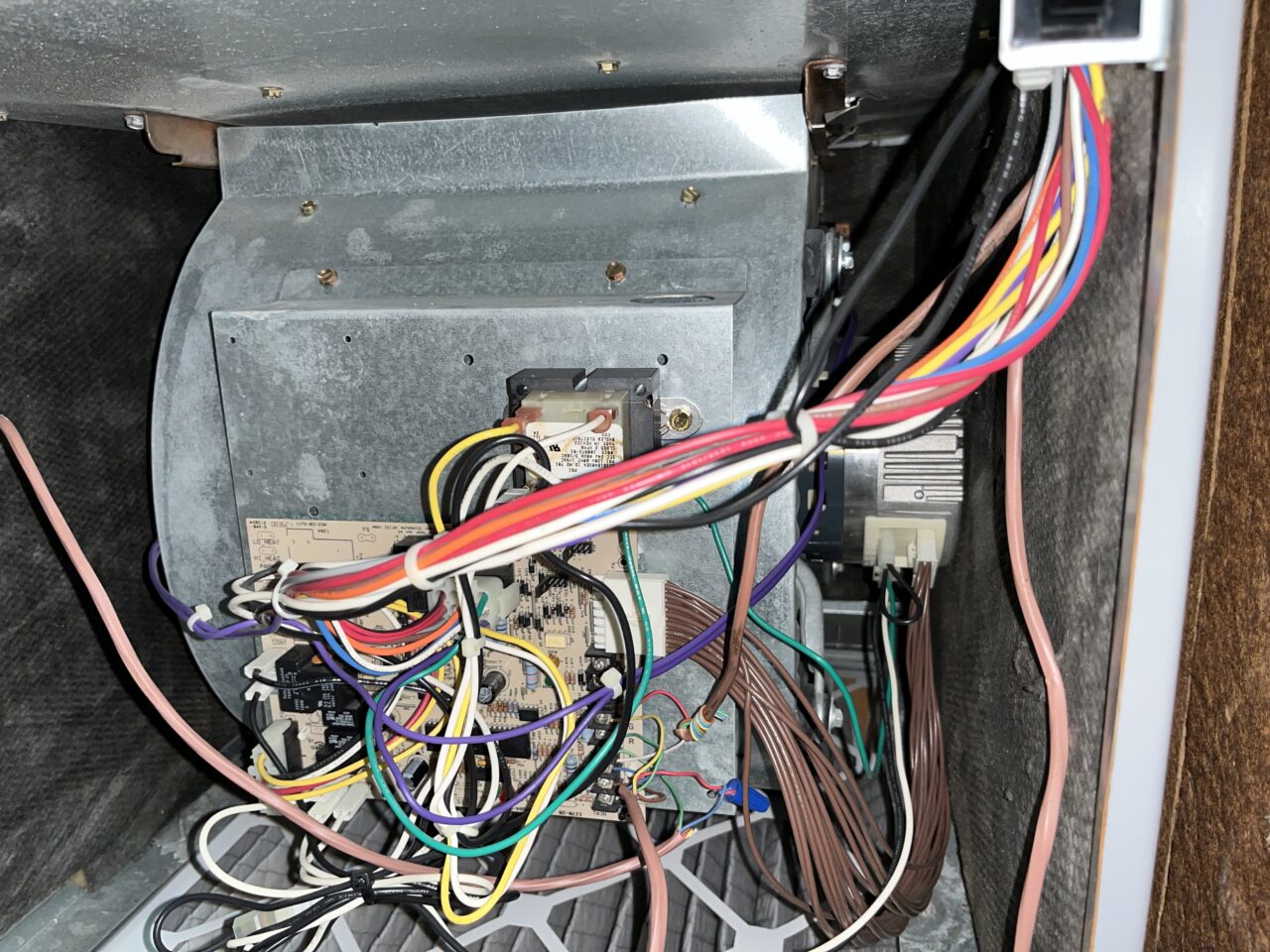

I was very curious what the inside of the motor controller looked like. I started by removing the large control circuit board which is attached to the blower housing by a large metal bracket and set that aside. Then I disconnected the blower wiring and attachment screws and removed the blower. Once I had the blower out, I was able to remove the motor controller from the back of the ECM motor.

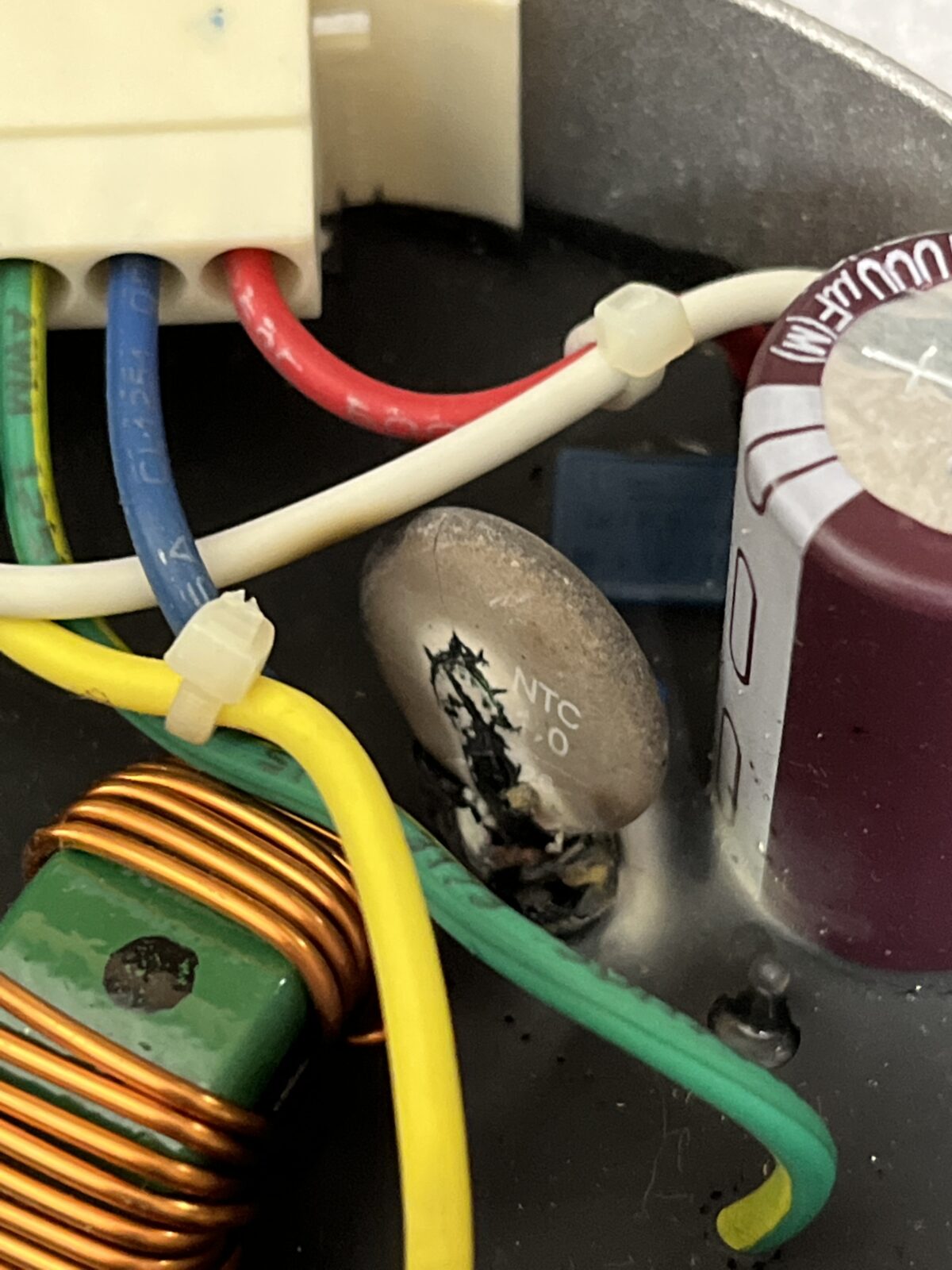

There was an obvious failed NTC Thermistor. NTC Thermistors are non-linear resistors, which alter their resistance with temperature. The resistance of NTC will decrease as the temperature increases. The MOSFETs that drive the motor windings looked to be in great shape and the huge heatsinks had done their job to keep them from overheating.

The original motor controller had an accessible circuit board, but on this board, everything was doped. The NTC Thermistor was mounted higher up above the doping for some reason. I was able to clip the leads and solder the new one onto the old part’s leads without having to remove much of the doping. I believe the doping is more of an anti-tamper mechanism than anything else.

I re-installed the controller onto the back of the ECM motor and then re-installed the blower assembly and control board and the various connections.

I flipped the FAN switch from AUTO to ON and the blower immediately came to life! Fixed!

These new “Electronically Commutated” (ECM) motors provide “soft start” and a more sophisticated motor speed control but they are much more expensive than “Permanent Split Capacitor” (PSC) motors. ECM motors must be configured for your specific application and are not interchangeable. I have not found any useful information on how this is done or what things are configurable about the motors.

Leave a Reply