Many years ago, Howard, KG6GI (SK) purchased a Generac 7550 EXL generator for his own use, but also as a backup for SOARA, should we ever need it. One year during field day, the primary generator failed and we were left to run on batteries that were quickly being depleted. Howard enlisted my help to go fetch his generator and we lugged the 245 pound beast to the field day site in time to find out that the problem with the primary generator had been resolved. It was a little low on oil, and that automatically shuts off the engine.

Recently Howard’s wife Lucy donated the generator to me to use but also to provide for SOARA use. It had not been run for many years. The gasoline had evaporated but left the tank surprisingly clean, so that was not a problem. This generator has electric start which is great, but the battery needed to be replaced and the starter switch had crumbled. I purchased a new Powersonic PSH12180FR flame retardant battery and found a “new old stock” starter switch on ebay.

Once I filled up the gas tank with fresh gasoline, and turned the fuel flow on, the carburetor spewed gasoline everywhere! Upon disassembly, I found that the needle that controls the flow of gasoline into the float bowl was stuck open. I cleaned the carburetor, reassembled everything, replaced the filters and the generator fired right up, no leaks!

I tested the output with a resistive load and it seemed to run fine.

Fast forward to field day 2021. The plan was to use two generators, the MV RACES generator and this one so that we could have one running while one was being refueled. Upon switching to the Generac generator we learned a valuable lesson. Test the output voltage and frequency before plugging anything into the generator! K6NR’s Powerwerx power supply was the unlucky victim of 160 VAC at likely the wrong frequency as well. The smoke was let out in a hurry. Sadly, Powerwerx does not repair their power supplies, nor do they provide schematics. I’ll be writing another article about repairing the SS-30DV supply. For what it is worth, we have had exceptional support and service from Astron, located in Irvine on repairing the clubs power supplies. Similarly, Samlex has been extremely helpful to me in repairing their supplies.

Once the generator was returned to my QTH by Heiko, Patti, Ray and Debbie, I was determined to figure out what went wrong. I started by reading through the owners manual and the engine owners manual which detail various versions and how they work. I learned that engine speed determines frequency and that voltage is managed by a control circuit inside the distribution panel. Not having a generator before, this was all new to me.

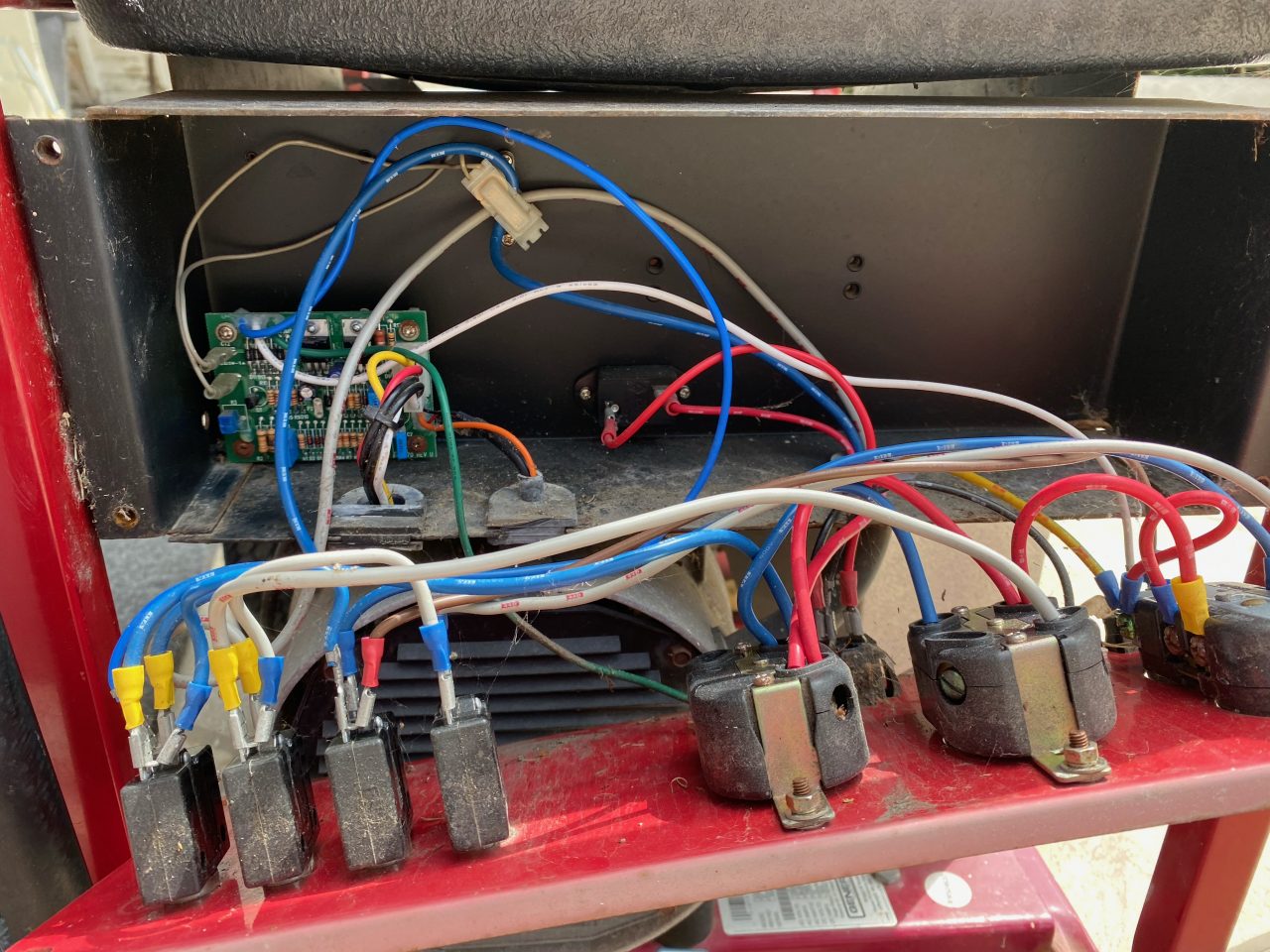

Adjusting the frequency was easy – there is a spring that provides a preload against the engines speed governor that you adjust. Adjusting the voltage is done through a little potentiometer on the side of the distribution panel. That pot had zero effect. The generator output was a solid 160 Volts AC!

Once I figured out how to remove the board, I put it on the bench to work on it. The board has been discontinued, however, “new old stock” boards are available via generator dealers on ebay for $250! That’s quite a lot to pay for a handful of parts on a circuit board with no ICs!

I read in a generator repair forum that the voltage adjustment pot sometimes goes bad and that was the first thing I tested. It was bad! The wiper was gone and presented a static 10K ohm resistance to the regulator board.

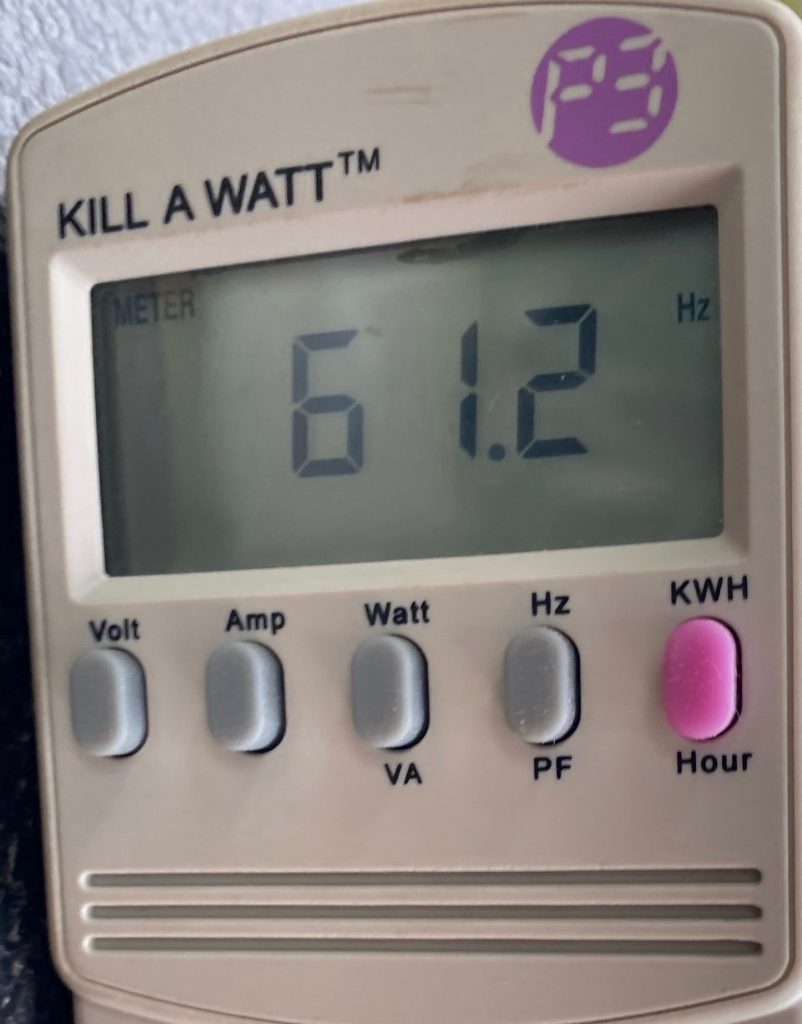

I replaced the pot, reinstalled the control board and fired it back up. The voltage was already lower, 137 VAC and was easily adjusted down to 120 VAC at 61.5 Hz. The frequency is adjusted a little higher to counteract the speed reduction under load.

So the take-away from this story should be that you should ALWAYS test the output of your generator before you hook anything up to it. It would also be wise to check the voltage from time to time during operation.

Leave a Reply