NJ6N’s Amateur Radio & Electronics Blog

-

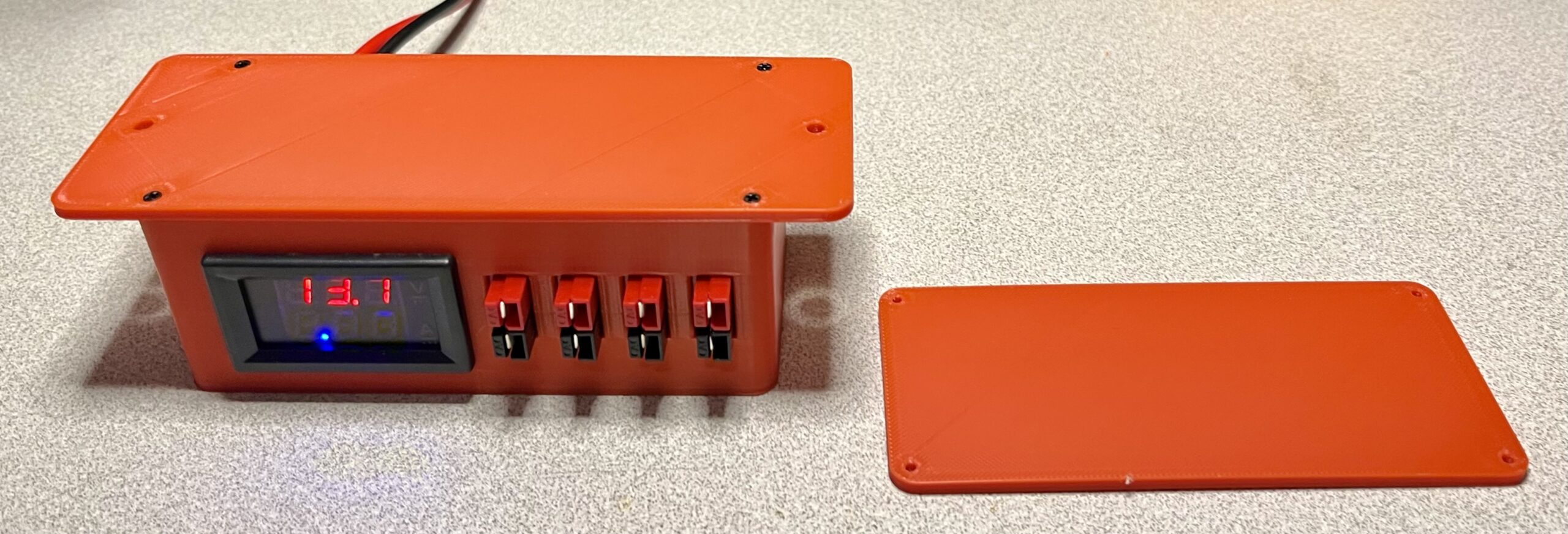

PowerPole Power Distribution

Here is yet another PowerPole power distribution box with a built-in Voltmeter and Ammeter. I designed two different covers, one for under-shelf mounting, and one for desktop use. The 3D STL files can be found on my Thingiverse page. After building version 1, I thought it might be good to have a fuse on the…

-

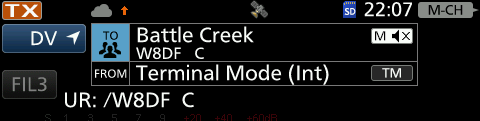

Icom G3 D-STAR Terminal & Accesspoint Mode

Terminal & AccessPoint modes enable you to use your IC-9700, IC-705, or ID-52 to communicate over the network, without using RF. Terminal and AccessPoint mode use either Callsign or Zone Routing. Callsign routing was more popular before reflectors and linking became available. In the early days of D-STAR, callsign routing enabled a ham who is…

-

OpenWebRX+

I’ve been running OpenwebRX+ for quite a long time now. Recently, a friend in Michigan asked me what I would use to provide a Ham who is out of reach of a repeater with the ability to listen to their weekly net. OpenWebRX immediately came to mind. I had last installed it back in 2023…

-

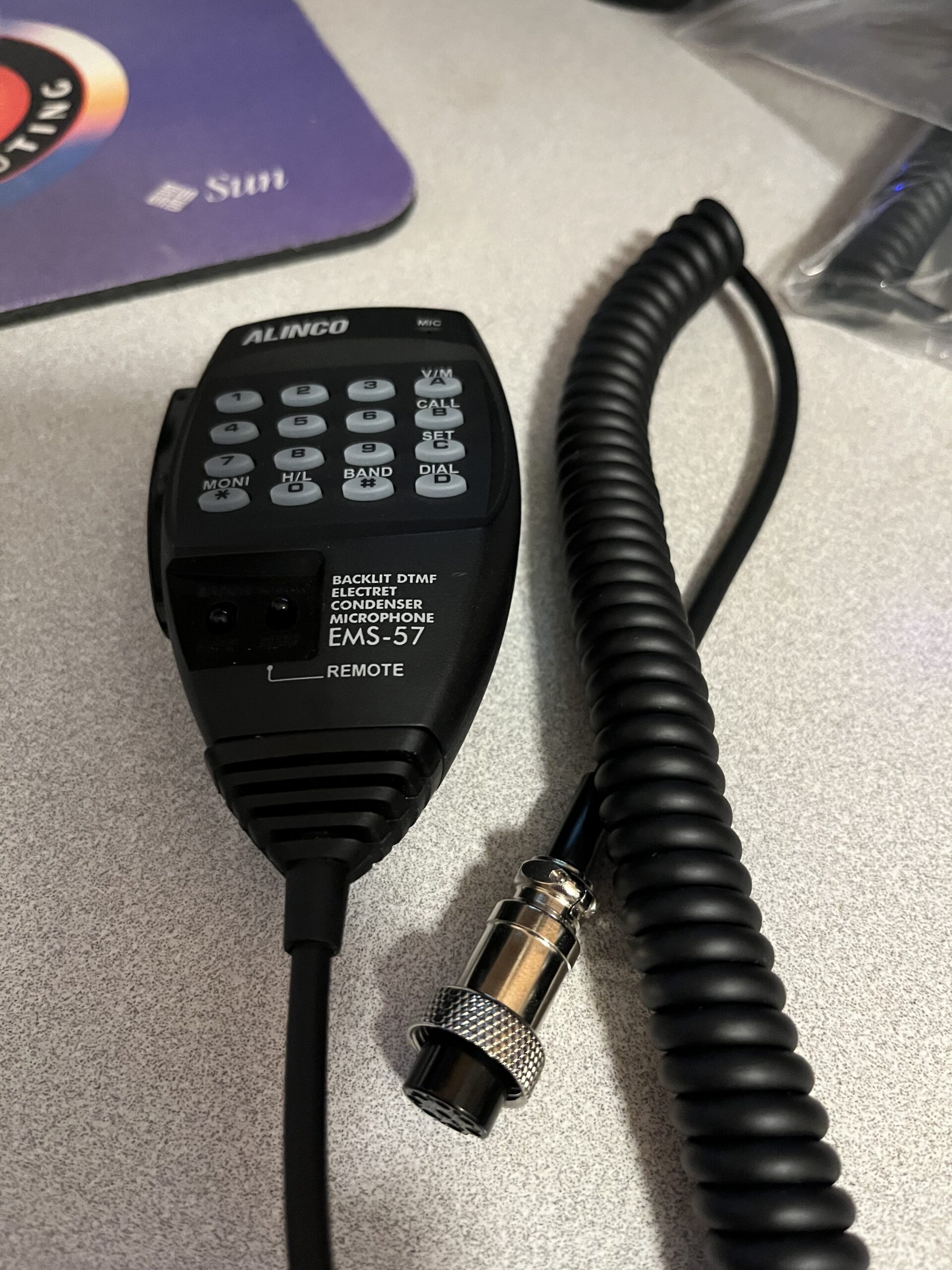

222 MHz Hot Spot & Repeater

I have always enjoyed the 1.25M band for FM. Recently I was going through my old radios and found two Alinco DR-235 mobile radios. One works great now that I replaced the mic cord. The other one is one that I bought on ebay as a “tech special” It has quite a few problems and…

-

Alinco EMS-57 Mic Cable

For some reason, the cords on my older microphones seem to be disintegrating. This has happened across all brands and is not isolated to just one. Looking at some of my older Alinco radios, most of the microphone cables are shot. The Alinco EMS-57 microphone has a very nice PCB area where the mic cord…

-

10 Meter Vertical Dipole

I recently built some coaxial vertical dipoles for the 6 meter band to use with my converted Maxtrac radio on FM. I designed a 50mm coil form with holes in the ends to capture the coax. 2 inch (~50mm) diameter PVC pipe would work also. I learned about this easy to build coaxial dipole from…

-

Batteries America EMS-20-28 Charger Repair

I recently came across an aftermarket rapid battery charger for an old Alinco DJ-280 220 MHz Handie-Talkie. When I plugged it in, there were no signs of life. So, I looked inside and found a very crispy 1/2 watt resistor in circuit with an NPN transistor. I had to guess at the value of the…

-

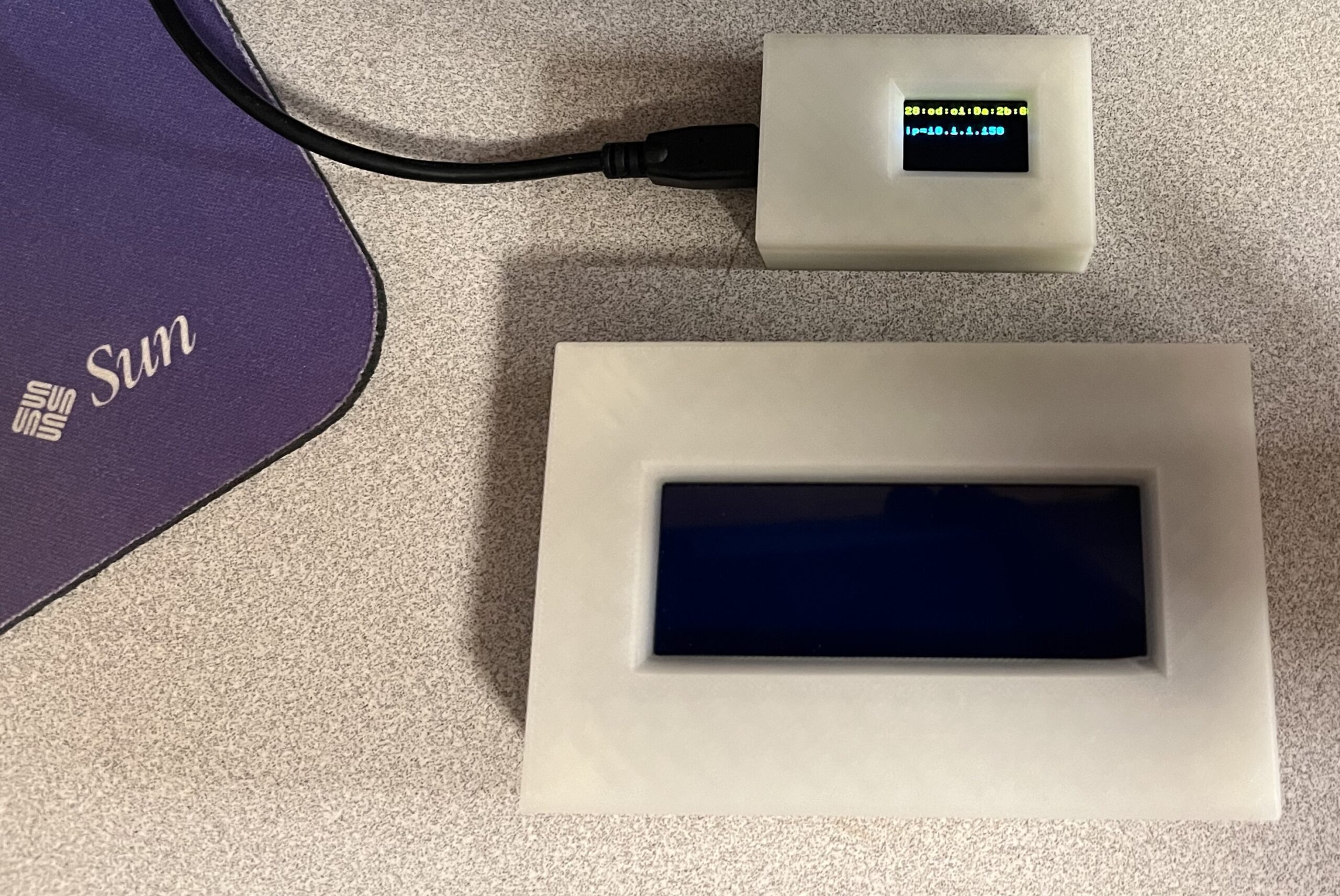

Fun with (IoT?) Displays

At one of the repeater sites there is a remotely addressable power control system. Right now we’re running on emergency generators after a fire took out the power distribution system to the mountain. I thought it might be useful to have a remote display that would reflect the site status. Towards that end, I wired…

-

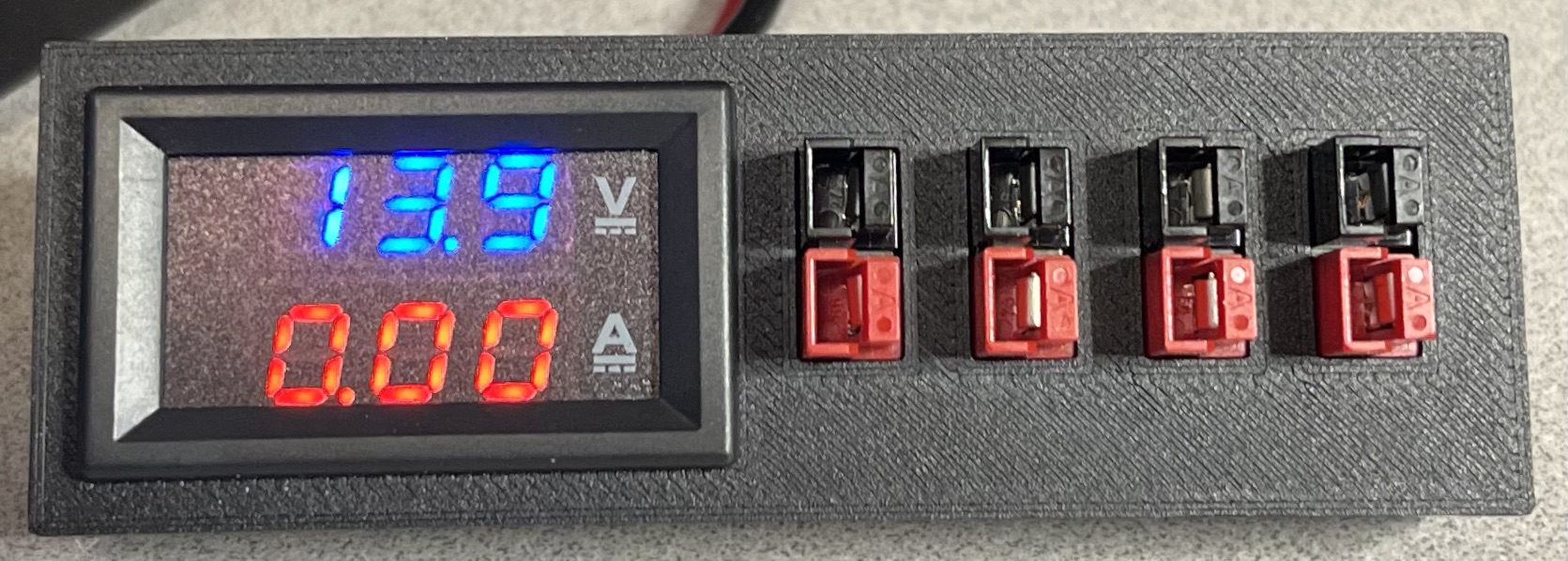

Convenient Workbench Power

The super convenient under-shelf Anderson Powerpole distribution panel that I made some time ago started to show signs of wearing out. The connectors had become loose inside the PLA. So, I designed a new version that’s similar to a standalone tabletop Powerpole distribution strip that I built recently. Instead of having flush mounted Powerpole connectors,…

-

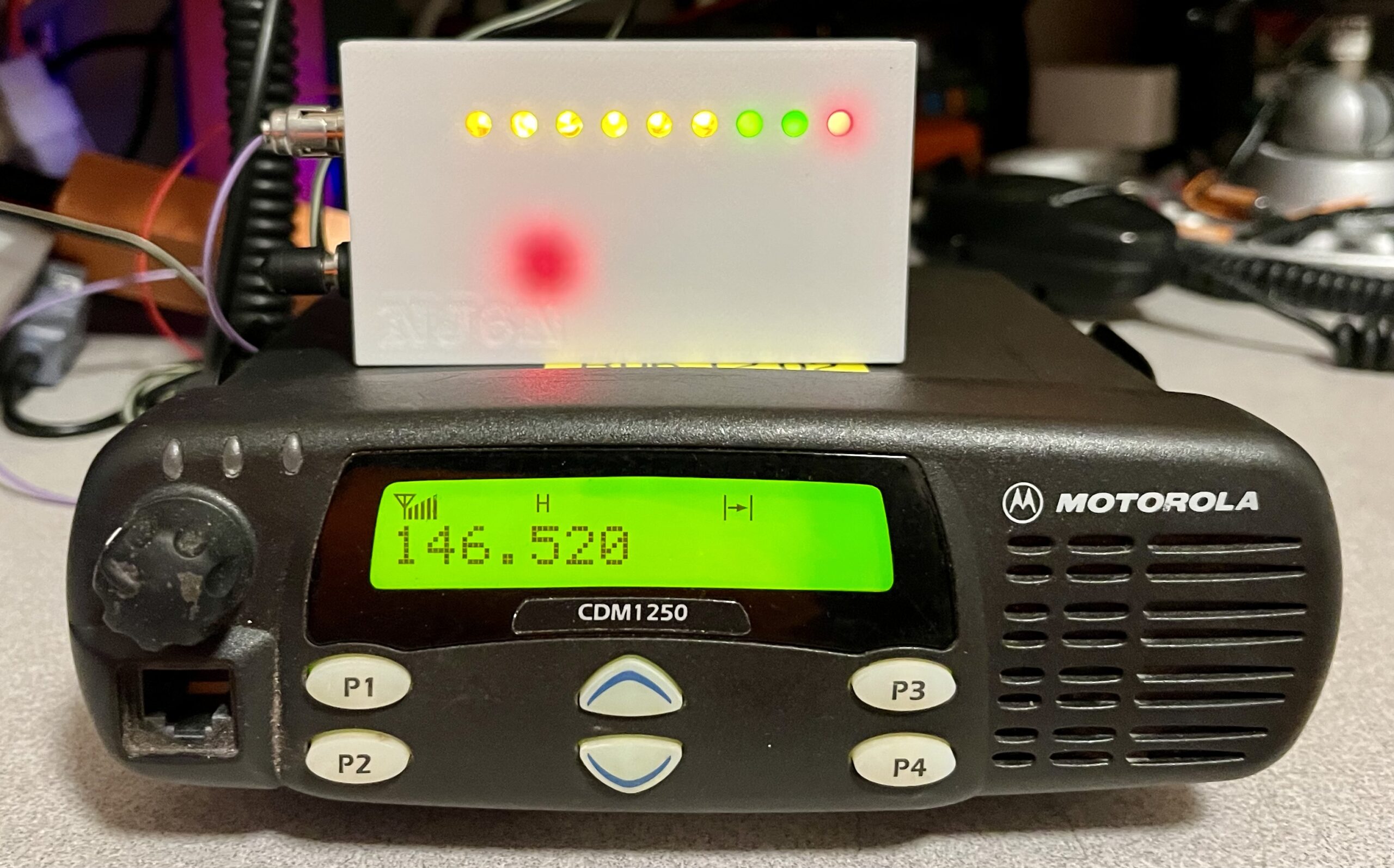

LED S-Meter for /\/\otorola

I have been using Motorola CDM-750/1250/1550 radios to build digital and analog repeaters, full duplex links, and digital hotspots for some time. Quite a few of the radios I have do not have a front panel display. However, they do have a 16 pin accessory jack that has all of the usual signals including TX/RX…

Got any book recommendations?